Kimla universal cutters are devices used for cutting with an oscillating or drag knife. All cutters are equipped with an active knife controlled by servo drives. Machines with an oscillating knife can have pneumatically or electrically powered heads. Pneumatic heads are high-frequency heads that enable very high feed rates to be achieved in soft materials. Pneumatic heads are used for extremely efficient processing of low-density foamed materials.

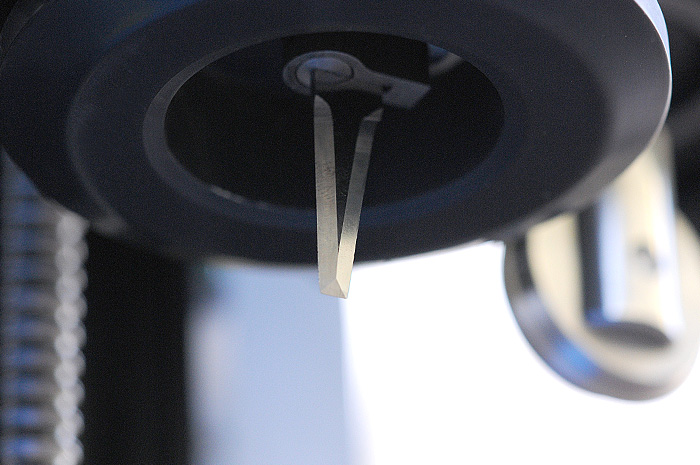

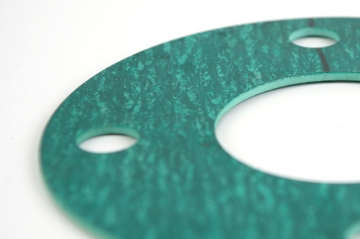

For the processing of harder materials with higher density, such as gasket materials, also those reinforced with mesh and steel sheet, we recommend electric heads, which have very high power, thanks to the use of two servo drives. One servo is used to set the knife angle and the other is to drive the oscillation. The unique power of the head can be obtained by using a 0.4 kW motor. This allows for the production of work in various materials, even those previously considered impossible to cut with a cutter.

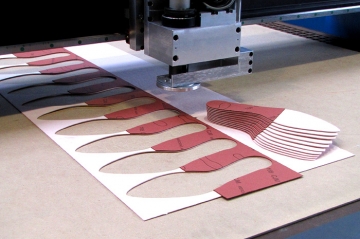

Universal cutters are also used for single-layer or multi-layer cutting of fabrics. To fix the materials, vacuum or vacuum tables divided into sections are used, which enables work on many work areas. All machines are equipped with control panels with an industrial control computer with appropriate software. The software, in addition to machine control, allows you to prepare the tool path and perform optimal layout (nesting). This allows for maximum use of the material with a very short preparation time.

Basic options

|

Working area dimensions

[mm] |

Width | 1000, 1300, 1500, 1700, 2100, 2600, 3000 ... |

|---|---|---|

| Length | 1500, 2000, 2100, 2500, 3100, 4100, 5100 ... | |

| Z axis range | 100, 200, 250 | |

| Oscillating knife | pneumatic | |

| electric - 1x servo, 2x servo | ||

| Control system | AC High Speed digital servo drives | |

| Table type | Vacuum | |

| Vacuum | ||

| T-slot | ||

| Hybrid | ||

| Control cabinet with a control computer | ||

Additional Options

| Oil mist cooling | Automatic | |

|---|---|---|

| Heads | Milling | |

| Creasing | ||

| Marking | ||

| Writing | ||

| Scanner | Touch | |

| Laser | ||

| Rotary axis | "B" on the table | |

| "C" on the spindle (for angular aggregates for saws and cutters) | ||

| Remote console | ||

| Pressure foot | ||

| Pressure mats | ||

| Homing system | ||

| Camera targeting system | ||

| Spindle | ||

Knife, creaser, camera

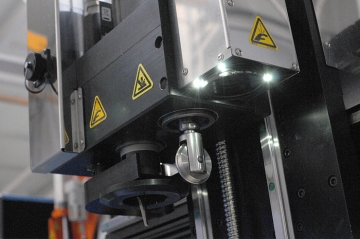

Oscillating head

Seal cutting

Cutting with an active knife

Cutting

Cutting cardboard

Cutting-milling router

Cutter with optional milling head (spindle)

Touch scanner

Electronics storage

Electronics

Cutting corrugated board on a cutter

Felt cutting on Kimla CNC Cutter

High speed cutter and 80mm cardboard

Insulating material cutting on Kimla CNC Cutter

Cardboard cutting on Kimla CNC Cutter

Car mats cutting on Kimla CNC Cutter

MultiMill on high speed cutter

Cardboard cutting on Kimla CNC Cutter

Blackbird with oscillating knife and creasing wheel

Cutter tool for upholstery materials

Multilayer fabric cutting

EPE foam cutting

Automatic vision marker recognizing

CNC cutter - cutting footwear parts

The fastest CNC cutter - max feed 1.7m/s

Table for cutting - high speed 1.7m/s

Cutting mineral wool

Cutting a seal from a reinforced plate

polyester sheet, active knife

Car carpeting cutting

Leather creasing and cutting

Reinforced graphite seal cutting

Cutting leather with a thickness of 5mm, 100mm/s

Cutting 12mm rubber

Cutting microporous rubber

Cutting with an oscillating knife

Sample Configuration

Universal HighSpeed cutter

Blackbird cutter

Universal cutter BPT2131