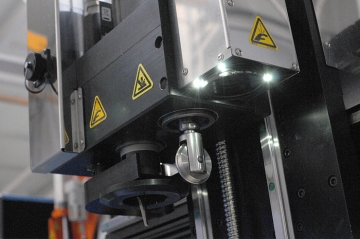

The world's first production cutter with Linear motors, opens new production capacity in many industries. The KIMLA linear Cutter BPT Linear is available in different workspaces and equipment options. The compact design of the machine has been equipped with innovative solutions based on linear drives, which are designed and adapted specifically for this device.

New generation Cutter

The new cutter with linear drives and a completely new design achieves even greater efficiency and quality of work. High efficiency cutting is possible through the use of direct measurement system positions with ultra high accuracy - measurement resolution of 0.001 microns and repeatability 1 micron positioning. Linear actuators used in this machine are virtually maintenance-free, because the magnetic drive does not cause any friction, so nothing wears out, which eliminates costly repairs during the lifetime of the machine.

Dedicated control system

Our original control system with dynamic analysis of vectors ™ has been specifically designed for the device so as to maximize the potential of our linear motors. From now on even very complex shapes can be machined with unprecedented efficiency and precision. Built-in all-in-one includes all required modules of CAD / CAM / CNC / NESTING which ensures comfort and precision machining.

Machined materials

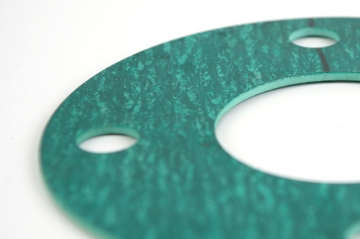

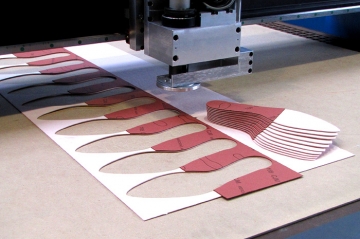

The Kimla BPT Linear offers a wide range of workpiece materials thanks to the expansion capabilities of many additional options. Will be perfect for cutting leather, textiles, fibers, composite materials, gasket, layered, paper, cardboard, foil.

Additional options

A table conveyor, which automatically moves the material which increases comfort and productivity. Enables continuous operation which reduces unnecessary downtime of the machine. In addition, the machine can be equipped with a receiving table and loading, sighting system, oscillating heads, milling heads, writing head, marking head, creasing head.

Basic options

|

Working area dimensions

[mm] |

Width | 1800, 2200, 2700, 3200 ... |

|---|---|---|

| Length | 1600, 2100, 2500, 3100, 4100, 5100, 6100 ... | |

| Z axis range | 200 | |

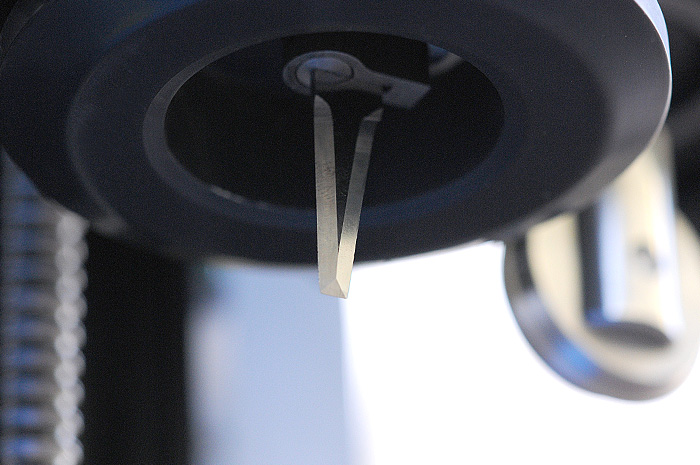

| Oscillating knife | pneumatic | |

| electric - 1x servo, 2x servo | ||

| Control system | AC High Speed digital servo drives | |

| Table type | Vacuum | |

| Control computer | ||

Additional Options

| Heads | Milling | |

|---|---|---|

| Creasing | ||

| Marking | ||

| Writing | ||

| Scanner | Touch | |

| Laser | ||

| Remote console | ||

| Pressure mats | ||

| Homing system | ||

| Conveyor - belt transport table | ||

| Receiving and loading table | ||

Knife, creaser, camera

Oscillating head

Seal cutting

Cutting with an active knife

Cutting

Cutting cardboard

Cutting-milling router

Cutter with optional milling head (spindle)

Touch scanner

Electronics storage

Electronics

Linear cardboard cutting and creasing

Cutting and creasing cardboard on BPT linear

Sample Configuration

HighSpeed Linear cutter with convector