5-axis CNC milling machines are devices that are used to make large-size details. The most common are casting, thermoforming and laminate molds. These machines can be used in a very wide range of work areas.

They are equipped with a high-class control system that allows for simultaneous interpolation of all axes with the projection of the working speed on the front of the tool. Five-axis CNC milling machines are also used to perform production machining after thermoforming or laminating. Finishing work, cutting off risers and shape workings can be processed on the basis of scanned shapes with a touch head. This allows you to perform finishing work without the need for expensive CAM software.

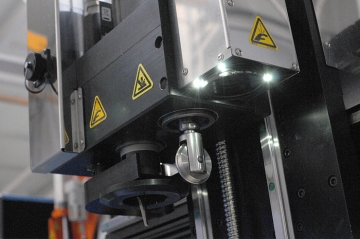

Five-axis machines are equipped with spindles from 5kW to 30kW. Kimla's 5D milling heads are built on the basis of backlash-free harmonic gears by the German company Harmonic Drive. This ensures high stiffness while maintaining very high efficiency and dynamics of movements. Thanks to the use of an innovative control system, the efficiency of Kimla's 5-axis CNC milling machines exceeds many times similar solutions offered by other manufacturers.

Basic options

|

Working area dimensions

[mm] |

Length | 1500, 2000, 2100, 2500, 2600, 3000, 3100, 4000, 4100, 5000, 5100 .. 24000 * | |

|---|---|---|---|

| Width | 1500, 2100, 2600, 3100 .. 5000 * | ||

| Z axis range | 700, 800, 900, 1000 ... 2000 | ||

| A axis range [degrees] | ± 130 ° | ||

| C axis range [degrees] | ± 213 ° | ||

| Spindles | 18,000 rpm | 6kW, 7.5kW, 12kW, 16kW, 18kW, 25kW | |

| 24,000 rpm | 6kW, 8kW, 9kW, 12kW, 13kW, 16kW, 18kW | ||

| 50,000 rpm | 2.4kW, 4.8kW | ||

| Cooling | Air, liquid + chiller | ||

| Control system | AC High Speed digital servo drives | ||

| Automatic Tool Change (ATC) | Line warehouse | ||

| Rotary warehouse | |||

| Table type | T-slot | ||

| Vacuum | |||

| Hybrid | |||

| Automatic tool length compensation | |||

| Control cabinet with a control computer | |||

Knife, creaser, camera

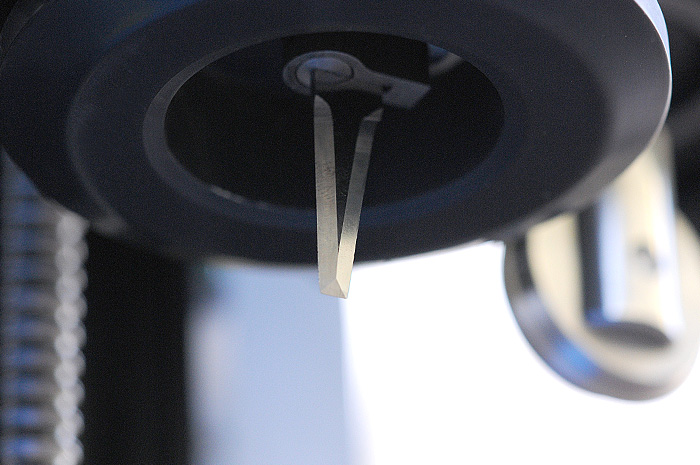

Oscillating head

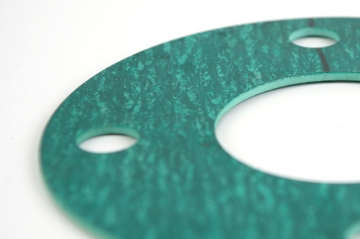

Seal cutting

Cutting with an active knife

Cutting

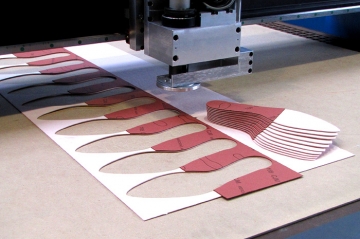

Cutting cardboard

Cutting-milling router

Cutter with optional milling head (spindle)

Touch scanner

Electronics storage

Electronics

Cutting corrugated board on a cutter

Felt cutting on Kimla CNC Cutter

High speed cutter and 80mm cardboard

Insulating material cutting on Kimla CNC Cutter

Cardboard cutting on Kimla CNC Cutter

Car mats cutting on Kimla CNC Cutter

MultiMill on high speed cutter

Cardboard cutting on Kimla CNC Cutter

Blackbird with oscillating knife and creasing wheel

Cutter tool for upholstery materials

Multilayer fabric cutting

EPE foam cutting

Automatic vision marker recognizing

CNC cutter - cutting footwear parts

The fastest CNC cutter - max feed 1.7m/s

Table for cutting - high speed 1.7m/s

Cutting mineral wool

Cutting a seal from a reinforced plate

polyester sheet, active knife

Car carpeting cutting

Leather creasing and cutting

Reinforced graphite seal cutting

Cutting leather with a thickness of 5mm, 100mm/s

Cutting 12mm rubber

Cutting microporous rubber

Cutting with an oscillating knife

Sample Configuration

5D BFN2141 CNC milling machine

5D CNC milling machine

5D CNC milling machine

5D BFN2532 CNC milling machine

5-axis CNC milling machine

5-axis CNC large- format milling machine

CNC 5D milling machine for foams and sponges BFN2131

Large-format milling machine for 5D CNC models

BFN2232 CNC 5D milling machine for foams and sponges

5D BFN2240 CNC milling machine

Five-axis CNC milling machine for models

5-axis CNC milling machine

5 axis CNC milling machine for models

5-axis CNC milling machine for BPF 2560 models